First task since the least visit was competing preparation and painting of the remaining skins and top rib.

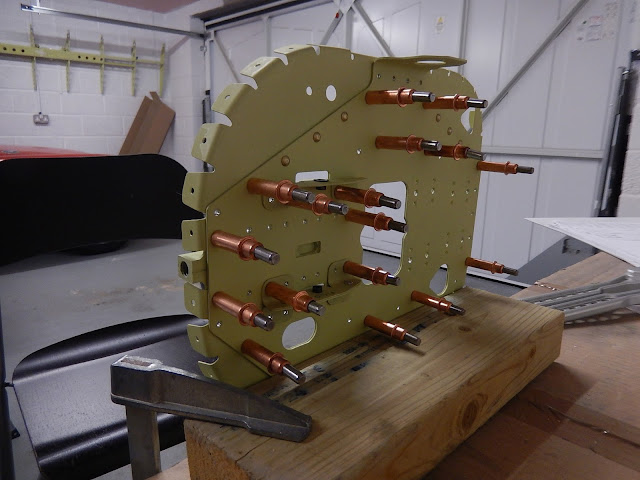

Fitting anchor nuts to the fin attachment rib which will go on the top tail cone skin

After the upper side skins were pinned in place, it's time to start out-fitting the tail cone. There's not a great deal in the rear - control cables for rudder and elevator, wiring for the electric trim, nav antenna cables and static pipework.

Strings fitted to pull-through the elevator and rudder cables (in about a year!). Also installed the pitch trim electric cable loom and the static port pipes to the ADAHRS.

You can just make out the inside of the left static port.

This is the right static port from the outside - it's a pop rivet with an over-sized head and the mandrel pushed out.

Now the final top skin is pinned in place, all holes match-drilled and then the skin removed again to deburr the holes. Finally, it's back on again and ready for riveting.

Top skin clecoed in place and ready to rivet.

You can see the remaining pins securing the skins to the fuselage frames.

The completed tail cone ready for inspection.

A top view of the fin attachment rib. The skin below the rib has been primed to prevent corrosion. The antenna connector is for the nav antenna in the fin cap, and allows for easy installation or removal of the fin.

Inside the completed tail cone.

My next job is to skin the horizontal stabiliser (HS). The skins are already prepped and painted. Moving on, it'll be a trial-fit of the fin/rudder and HS to the tail cone. At this stage, it will look like the complete rear-end to an aircraft! Once this is done, I have to deal with the trim motor mountings and then make the tail cone fibreglass fairings fit (apparently a bit long-winded to get good alignment with all of the securing brackets) . I reckon this will take me to the end of January, and then it'll be time to start on the wings.

To all readers - thanks for visiting and my best wishes for a Happy New Year.